If you want a new hydraulic filter for your machine, it is essential to know what type to get. There are several hydraulic filters, including high-pressure, high-efficiency, and return-line. This article will discuss all of them and how they can benefit your machine. Before contacting hydraulic filter suppliers VA, read our hydraulic filter article to learn more about each. Listed below are the pros and cons of each.

Hydraulic Filter Element

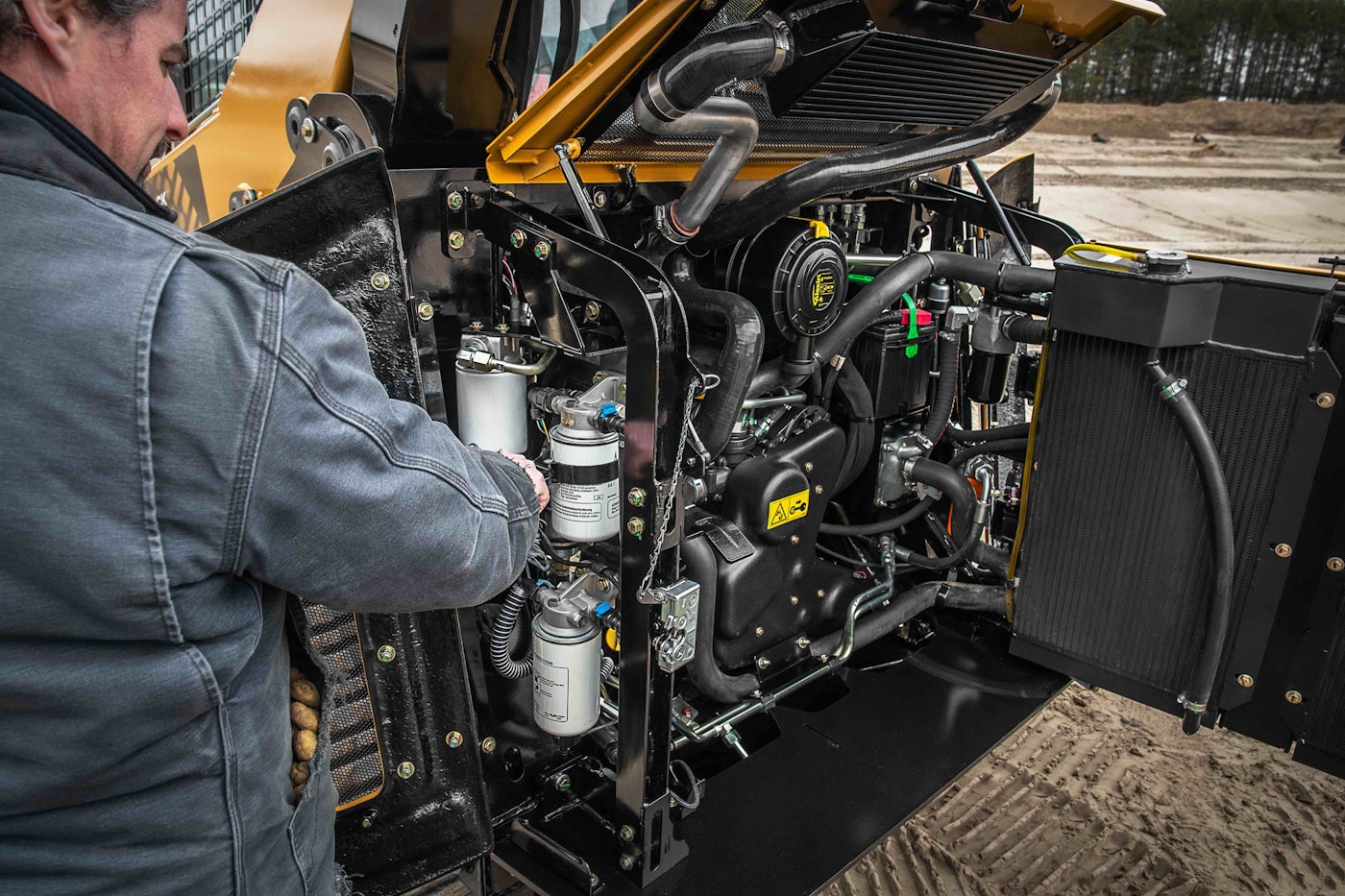

The hydraulic filter element is a mechanical part of a hydraulic system that traps and eliminates contaminants from the fluid. Hydraulic filters can remove dissolved water from various oils, making them an essential part of any hydraulic system. In addition, hydraulic filter elements can also remove contaminants from diesel and bio-fuels and the fluids in the hydraulic reservoir and transport. This type of filtration also improves safety in the workplace since the filter element helps to keep the oil and other fluids clean and free of contaminants.

One of the benefits of using this type of filtration is that the pore size is large, allowing the fluid to pass through it faster. Hydraulic filter elements come with a protective cage, which can be made of various materials and shapes. Depending on the application, the filter housing should be designed to fit the hydraulic filter element, allowing it to perform its job. The supporting tube should be able to support the filter media’s weight and withstand high pressure and temperature. The supporting line must be porous, allowing the fluid to pass through the hydraulic filter element without stopping the flow of the fluid.

High-Pressure

High-pressure hydraulic filter elements can be easily replaced if they become damaged or need to be replaced. This filter element is made of high-quality material that is inexpensive to purchase and easy to dispose of. The high-pressure filter element is durable and highly compatible with various types of high-pressure applications. Its high-dirt-holding capacity helps prolong its operational time. Moreover, it does not require frequent maintenance.

The pore structure of the high-pressure hydraulic filter element varies according to the contaminant content. The smaller the contaminants, the smaller the pore structure must be. The graded pore structure of high-pressure filter elements guarantees long-term service. The filter element’s sealing material may be permanent or replaceable, depending on the level of dirt and debris it needs to filter. The filter element’s end discs can also aid in filtration or stop the flow of fluid.

High-Efficiency

The beta rating of a high-efficiency hydraulic filter element indicates its ability to trap particles. The higher the beta value, the better the filter will protect your hydraulic equipment. The lowest beta rating will fail to protect a contaminant-sensitive servo valve. An ISO standard no. 16889:1999 provides information about this. The highest beta rating is 700. If it is too low, your system may fail.

The filtration rate is usually low if the hydraulic filter element is made of synthetic fiber. You must also change your filter elements frequently to ensure consistent high efficiency. Some filters are non-reusable, so it is essential to replace them when they become dirty. A high-efficiency hydraulic filter element should be cleaned at least once a year to maintain efficiency. It is important to clean the hydraulic filter element if it becomes dirty and clogged.

Return-Line System

The most common cause of a hydraulic pump failure is contaminated hydraulic fluid, which can affect its performance. Often people choose to replace the hydraulic pump rather than clean the fluid. Return line filters are a simple yet effective way to maintain the hydraulic system and ensure it is functioning at its best. The filter can remove small contaminants from the hydraulic fluid if used correctly. There are several types of return line filters on the market, and the proper selection depends on the application.

The Return-Line hydraulic filter system works by passing fluid through an inlet and a filter element. High pressure forces the fluid into the filter element, which filters it. The filter element then passes through a mesh, where it filters contaminants. Once filtered, the fluid flows back out through a drainage valve. The filtration process continues until the filter becomes clogged and needs cleaning. Self-cleaning backwash systems are the most common, and this method is most effective because it involves flowing water backward through the filter element, removing contaminants. Finally, the water flows out of the filter element and into a dirt-holding duct.

Micron Size

The quality of a hydraulic filter is based on the micron size of the contaminant particles it traps. The micron is one-millionth of a millimeter or 1,000,000 times smaller than a human hair strand. The size of a grain of salt is a hundred microns, while the diameter of a red blood cell is only three microns. These contaminant particles can cause hydraulic systems to fail. This is why choosing a filter that protects the most critical components is important.

A hydraulic filter element’s flow rate is also critical. A higher flow rate implies faster filtration so a larger micron size will be necessary. Additionally, the filter element must be able to handle the required flow rate. The size of the pore will determine the type of contaminants it can remove. The construction of the filter element will also depend on the application, as a hostile environment will require a more rugged construction.

Placement

A hydraulic filter is a mechanical device to reduce the amount of fluid passing through it. The hydraulic filter has two endplates. The main filtering material contains pleats, which increase surface area and filtration efficiency. O-rings are typically sealed between the upper-end plates and the filter body. The o-ring package will depend on the filter’s model and its manufacturer. It may be made from stainless steel wire or an aluminum alloy tube, which provides greater support to the hydraulic filter element.

In addition to their mechanical properties, hydraulic filters come in various form factors. Many people purchase a complete hydraulic filter, including the housing and the filter element. Replacement filter elements can be purchased separately, and you won’t need new housing. The filter housing directs the fluid through the filter media. You can buy hydraulic filters with proportional or full flow specifications, which refer to the volume of fluid that the filter can handle.